The Baby Corben Baby Ace airfoil is a modified Clark-Y. This airfoil is very old and has a proven track record for good flight characteristics. Most Baby Ace builders wouldn’t consider building the wings any other way, and for good reason, the plane flies great!

When looking at the blueprints the wing is easy to build and strong. The one complaint pilots have with the Baby Ace is the ailerons. They are well built,strong and easy to build, but can be a little stiff in flight. This is where I began my quest to figure out what to do about it. Keep in mind is you are interested in building this airplane most Baby Ace owners don’t look at this as a problem. They all seem to mention the stiffness but they are all happy building the airplane per plan.

As the builder I started to ask myself what could be done about this. Well, you know how things go, one thing lead to another and now I’m building a Baby Ace with a whole new airfoil.

Help from Harry Riblett

While searching different ways to change the ailerons I began to study different airfoils on similar type airplanes. This lead me to start thinking about changing the whole wing. The ailerons on the Baby Ace are big triangles and are mounted with a large gap. The plans show sheet metal screwed to the wing to create a gap seal, an obvious fix. Owners report this works very well. When looking at airplanes like the Cub, Taylorcraft, and the luscombe the ailerons have a type of airfoil shape to the front. The hinge point is also very different.

The study of airfoils can be a bit complicated so after some thinking I decided to call the EAA and ask for help. A conversation with Joe Norris put me in touch with airfoil expert Harry Riblett.I tell ya, once I had a conversation with him it became quite clear airfoil design is not for amateur’s. It took a while but he explained how to match an airfoil to an airplane and after a couple of weeks I now have a airfoil and ailerons designed to bring out the best qualities of the Baby Ace.

The best way to describe the airfoil is to think of a mutated NACA 4412, the same airfoil as found on the Luscombe. This airfoil is different however. According to Harry the stall and lateral stability at low speed of the new airfoil will be it’s best attribute. Another great feature is it should have an increase in speed. I should mention the ailerons should be a little smoother and a bit more responsive.

With the fuselage structure still being in the final stages the wings are not yet made. I have however built my wing rib jig and a sample rib. My hope this summer is to build the wings and mount them on the fuselage. As I build the ribs, wings, and ailerons, I will post pictures. Here are the coordinates for the Harry Riblett airfoil for the Corben Baby Ace. ( GA 30-612 )

| Station | Upper | Lower |

| 0 | 0 | 0 |

| 0.25 | 0.984 | 0.76 |

| 0.5 | 1.429 | 1.015 |

| 0.75 | 1.776 | 1.194 |

| 1.25 | 2.335 | 1.453 |

| 2.5 | 3.391 | 1.837 |

| 5 | 4.877 | 2.231 |

| 7.5 | 5.982 | 2.418 |

| 10 | 6.86 | 2.504 |

| 15 | 8.189 | 2.501 |

| 20 | 9.11 | 2.366 |

| 25 | 9.728 | 2.156 |

| 30 | 10.106 | 1.898 |

| 35 | 10.281 | 1.623 |

| 40 | 10.27 | 1.354 |

| 45 | 10.094 | 1.106 |

| 50 | 9.734 | 0.914 |

| 55 | 9.171 | 0.813 |

| 60 | 8.447 | 0.761 |

| 65 | 7.587 | 0.717 |

| 70 | 6.605 | 0.659 |

| 75 | 5.532 | 0.576 |

| 80 | 4.424 | 0.46 |

| 85 | 3.319 | 0.345 |

| 90 | 2.213 | 0.231 |

| 95 | 1.106 | 0.114 |

| 100 | 0 | 0 |

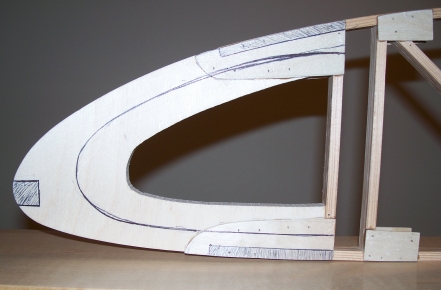

Wing rib jig photos of the new Baby Ace airfoil

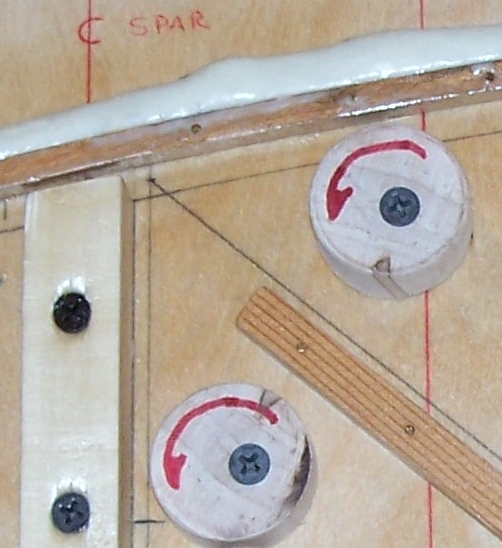

As you will see in the following pictures the rib jig I built is a little different than what most people tend to build. A typical jig for building the ribs has some pieces of scrap or capstrip nailed down on a board that the rib pieces fit into. The way I built mine is unusual in that I use a clamp made from a maple closet pole cut into about 3/4″ pieces with a hole drilled off center so when it rotates it forces and holds it into position. The best part of doing it this way is the positioning the capstrip that seats next to the spar blocks. On the drawings for the ribs you can see the spar opening on some ribs gets a little wider because of a plywood reinforcing plate on certain ribs. With my cam locks I don’t need to change anything on the jig because the cams are always pushing in one direction. Another benefit is the cams also keep the spar opening tight and doesn’t allow for any slop in the construction. See the photo below.

Corben Baby Ace wing jig cam system showing the upper front spar block

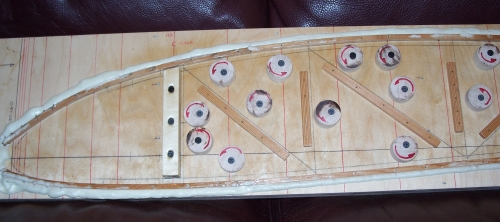

To build my jig flat and true I used two layers of plywood laminated with some 5/8″ Doug Fir 1/4 sawn strips. Then it’s just a matter of laying it out and drawing the curves.

Once it was drawn out I grabbed some 1/4″ capstrip and nailed it down along the curve. The cams put alot of pressure on the form so I thought it best to take some Gorilla Glue and run a bead around the outside to keep anything from moving while clamping.

In the next photo you can see a cross section of the jig itself. It’s a bit heavy but building it this way creates a near perfect rib.

Corben Baby Ace wing airfoil jig. Harry Riblett design

The black piece you see in the photo is the nose jig I plan to use for routing out the nose blocks. Its solid phenolic and very hard. It takes some time to make a good fitting nose jig, but with a little elbow grease and patience it comes out perfect.

Another simple jig

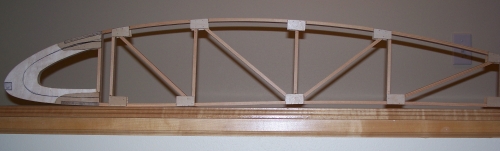

With the jig all done I started to lay my pieces of capstrip down. Bending the capstrip over the nose block was a little stiff so I ended up soaking the upper and lower capstrip in boiling water for 30 minutes then holding it in a jig for a day. Here is a photo of the bending jig.

The jig worked out perfect. As you can see in the photo the jig has a top and a bottom. The right side ( top ) has a larger angle because the airfoil on top has more curve than the bottom. After 30 min. in the water you just stick it in, bend it, then hold the capstrip with a block of wood and a clamp. I have pencil marks on the ends where the bend stops. The jig is set up to hold 4 pieces for the top and 4 pieces for the bottom.

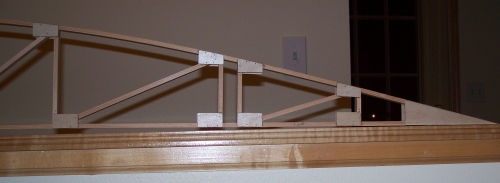

The first sample rib

In the next post I’ll explain a little about the rib itself.

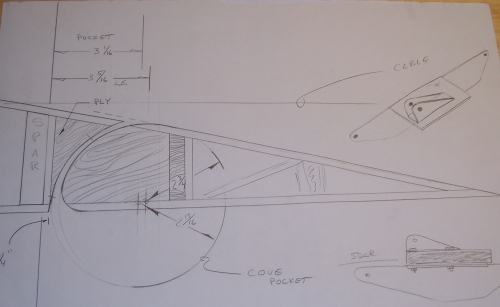

Ailerons

I’m starting to work on the aileron design. This is what I have so far.

First sketch for new Baby Ace ailerons

Hi I am rebuildin My Baby Ace D after flying it fo ten years I just sand blated the fuselae today. I have not started on the wings yet but the one complant about the ace is the ailerons so the article is interesting to me…I was thinking of keeping the same airfoil with freise type ailerons. I might be interested in a total rebuild…Mike

I think the Pober Jr Ace uses a much advanced aileron simlar to what you are working on. It is shown as an option in the plans.

Mike, I’m tying to clarify the different posts and comments on the GA30-612 airfoil. Your web site lists the lofting coordinates and refers to them as “for the Harry Riblett airfoil for the Corben Baby Ace, (GA 30-612)”. Would these coordinates be the same for a Pietenpol?

Thanks for your response.

Allan Macklem